Home » Electric boiler » Electric Heating Steam Boiler

Product Description

1-10t/h 1.0-1.25Mpa

Rated steam capacity :1-10t/h; Rated working pressure :1.0/1.25Mpa; Staturated steam temperature :184/193℃; Input power : 720-7200KW; Rated voltage :3N AC 50Hz 380V; Fuel :Electric heating;etc. Industry :Foods, Garment, Taextile, Paper, Brewery, Ricemill, Dairy Products, Laundry, Poultry feed, Package, Plywood, Building material, Chemical, etc.The boiler furnace is separated from electrical control cabinet to avoid the aging of electrical heating element .

Above products are powerful horizontal steam boilers.The boiler furnace is separated from electrical control cabinet to avoid the aging of electrical heating element . Electrical heating tube with high quality with normal service life around 20,000 hours.Thermal efficiency is nearly 99% ,quiet operation, clean, environment friendly,no atmospheric emissions of NOx (nitrogen oxides). Boiler running with PLC control system, free button operation, free signal light, touch-screen panel, Chinese& English, the man-machine dialogue, authorized operation, real-time information, automatically turning pages.

2.Each heating element use a concentrated beam flange connection,independently arrangement, simple structure, high mechanical strength, safe, reliable, convenient replacement, long service life.

3.Large steam room ,super quality steam.

4.Boiler and control cabinet is seperated ,so control components could away from heat source .One set or many sets could together for multi-usage.

5.PLC microcomputer programmable control and display screen. Automatic water outlet temperature control settings. Screen displays equipment operating parameters and fault alarm.

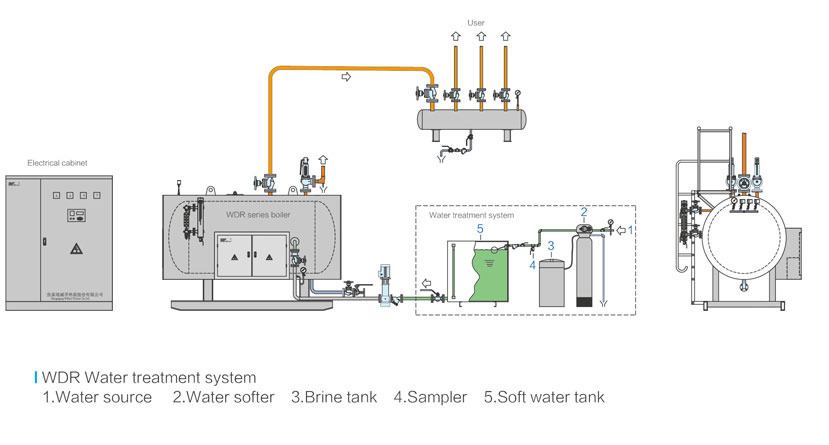

Product system Drawings

Product Detail Analysis

Technical Parameters

| Model | WDR1 | WDR1.5 | WDR2 | WDR3 | WDR4 | WDR6 | WDR8 | WDR10 | ||

| Project | Unit | |||||||||

| Rated evaporation | T/h | 1 | 1.5 | 2 | 3 | 4 | 6 | 8 | 10 | |

| Rated working pressure | MPa | 1.0 | 1.0 | 1.0 | 1.25 | 1.25 | 1.25 | 1.25 | 1.25 | |

| Staturated steam temperature | ℃ | 184 | 184 | 184 | 193 | 193 | 193 | 193 | 193 | |

| Input Power | KW | 720 | 1080 | 1440 | 2160 | 2880 | 4320 | 5760 | 7200 | |

| Input current | A | 1080 | 1620 | 2160 | 3240 | 4320 | 6480 | 8640 | 10800 | |

| Rated voltage | V | 380V | 380V | 380V | 380V | 380V | 380V | 380V | 380V | |

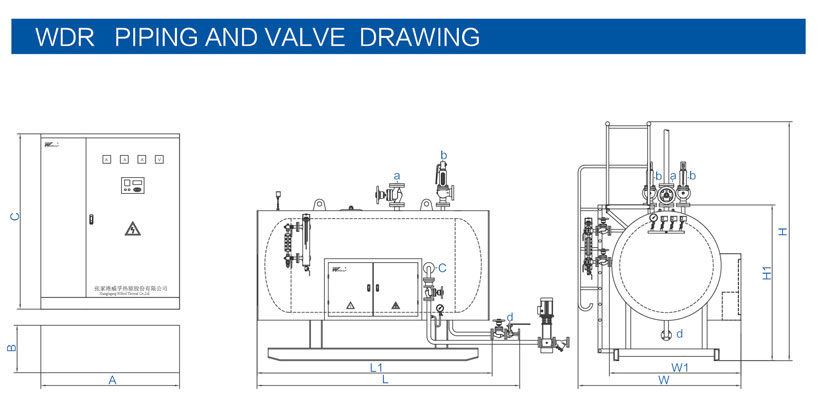

| a Main steam valve diameter | DN | 40 | 65 | 80 | 80 | 100 | 125 | 150 | 150 | |

| b Safety valve diameter | DN | 2×40 | 2×40 | 2×40 | 2×40 | 2×50 | 2×50 | 50+80 | 2×80 | |

| c Inlet diamater | DN | 25 | 25 | 25 | 40 | 40 | 40 | 40 | 50 | |

| d Blowoff Valve diameter | DN | 40 | 40 | 40 | 50 | 50 | 50 | 50 | ||

| Overall size | L | mm | 2600 | 3000 | 3200 | 3950 | 4100 | 4500 | 5800 | 7200 |

| L1 | mm | 2400 | 2700 | 2880 | 3300 | 3550 | 4300 | 5400 | 6500 | |

| W | mm | 1900 | 2000 | 2000 | 2300 | 2300 | 2300 | 2300 | 2300 | |

| W1 | mm | 1600 | 1880 | 1880 | 2260 | 2260 | 2260 | 2260 | 2260 | |

| H | mm | 2100 | 2500 | 2500 | 2650 | 2880 | 2880 | 2980 | 2980 | |

| H1 | mm | 1800 | 2100 | 2100 | 2100 | 2200 | 2300 | 2300 | 2300 | |

| Electrical control cabinet size | A | mm | 1200 | 1800 | 2200 | 2200(2pcs) | 2200(2pcs) | 2200(3pcs) | 2200(4pcs) | 2200(5pcs) |

| B | mm | 600 | 600 | 600 | 600 | 600 | 600 | 600 | 600 | |

| C | mm | 2000 | 2200 | 2200 | 2200 | 2200 | 2200 | 2200 | 2200 | |

| Weight | T | 1.8/2.2 | 2.2/2.7 | 2.8/3.3 | 3.5/4.1 | 4.5/5.2 | 6.8/7.2 | 7.8/9.4 | 9.4/11.5 | |

Company Information

One Solution, One Partner

20+ years experience. We supply the whole solution of boilers and boiler systems — from selection to installation support.